Aluminium Die Casting

Aluminium Die Casting at Vision Metal Cast

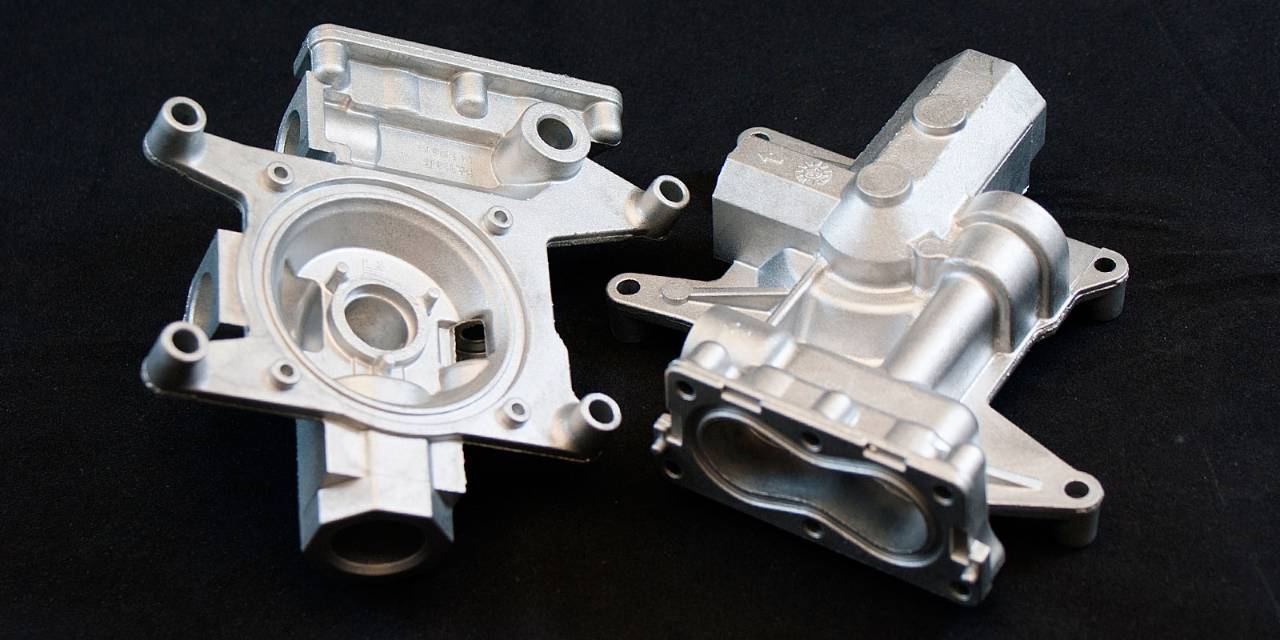

Aluminium die casting is a highly efficient manufacturing process used to produce complex and precise components. At Vision Metal Cast, we specialize in this technique, leveraging advanced technology and expertise to deliver high-quality aluminum parts tailored to various industries.

Process Description

Die Casting Process

Aluminium die casting involves melting aluminum and injecting it into a precision-crafted mold (die) under high pressure. This method enables the creation of intricate shapes and components with tight tolerances. Once the aluminum cools and solidifies, the mold is opened, and the finished part is ejected, ready for further processing or assembly.

Types of Die Casting

At Vision Metal Cast, we utilize both hot chamber and cold chamber die casting techniques. The choice of method depends on the specific requirements of each project, ensuring optimal efficiency and quality in the production process. Hot chamber die casting is ideal for low-melting-point alloys, while cold chamber is suited for higher temperature materials.

Benefits of Aluminium Die Casting

Lightweight and Durable

Aluminium components produced through die casting are significantly lighter than those made from alternative metals, offering an excellent strength-to-weight ratio. This property makes them particularly advantageous in industries where weight reduction is critical, such as automotive and aerospace.

High Dimensional Accuracy

The precision inherent in the die casting process ensures that parts are produced to exact specifications. This minimizes the need for post-processing, reducing production time and costs while maintaining high quality.

Complex Geometries

Our advanced die casting technology allows for the creation of complex geometrical designs that might be challenging or impossible to achieve through other manufacturing methods. This capability enables us to meet diverse design requirements across various industries.

Applications

Automotive Industry

Vision Metal Cast supplies aluminum die cast components for a range of automotive applications, including engine parts, transmission housings, and structural components. Our parts contribute to the development of lighter, more fuel-efficient vehicles.

Consumer Electronics

We manufacture durable enclosures and structural parts for consumer electronic devices, ensuring both functionality and aesthetic appeal. Our die cast components support the evolving designs and technological advancements in this fast-paced industry.

Industrial Equipment

Our aluminum die castings are widely used in various industrial applications, offering the reliability and efficiency needed for demanding operational environments. These components are designed to withstand the rigors of industrial use.

Automotive Industry

Vision Metal Cast supplies aluminum die cast components for a range of automotive applications, including engine parts, transmission housings, and structural components. Our parts contribute to the development of lighter, more fuel-efficient vehicles.

Sustainability Commitment

We prioritize sustainable practices in our die casting operations. Aluminium is a highly recyclable material, and we strive to minimize waste and energy consumption throughout our manufacturing processes. Our commitment to sustainability not only benefits the environment but also aligns with the values of our clients and partners.