WHAT WE CAN OFFER

Our Capabilities

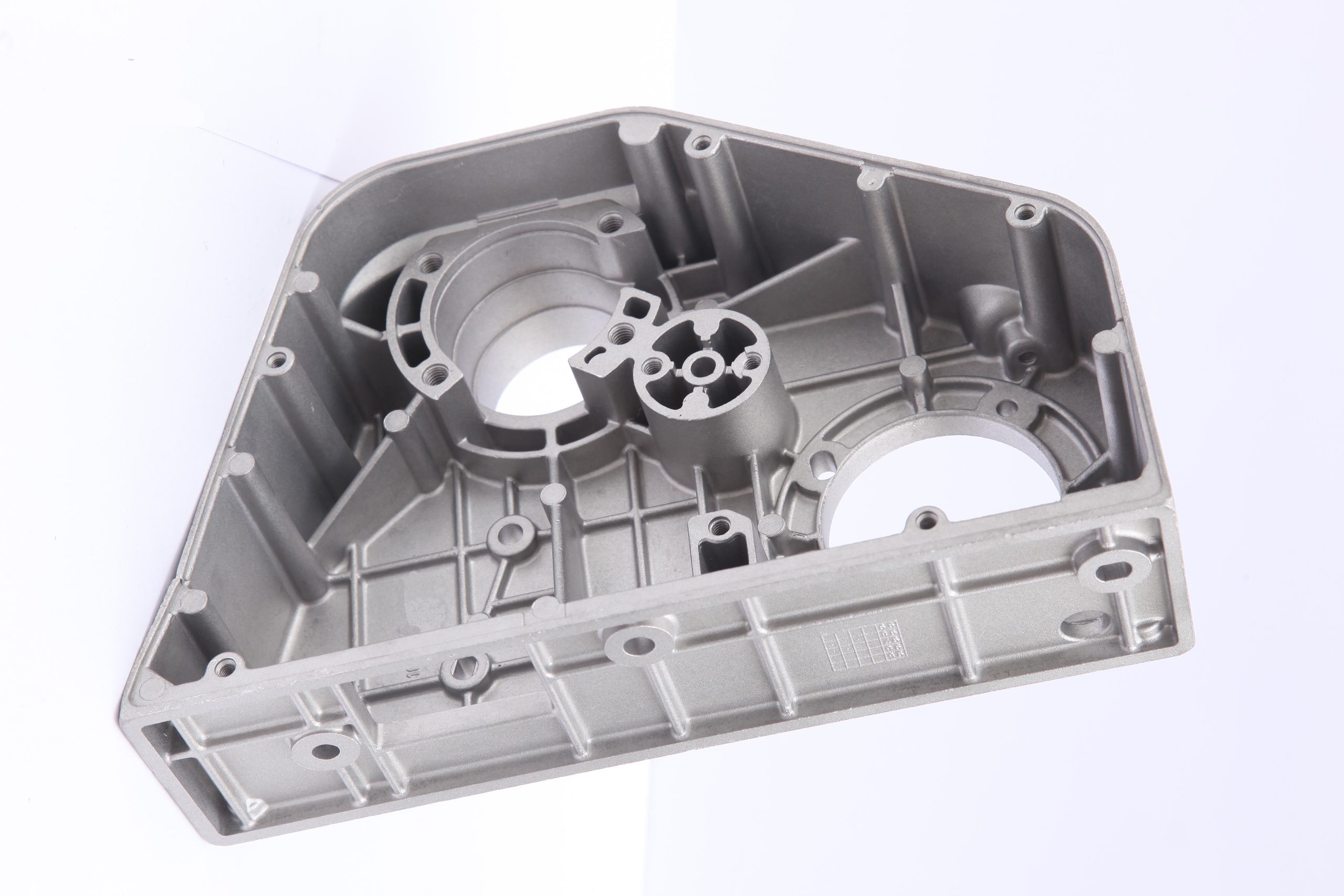

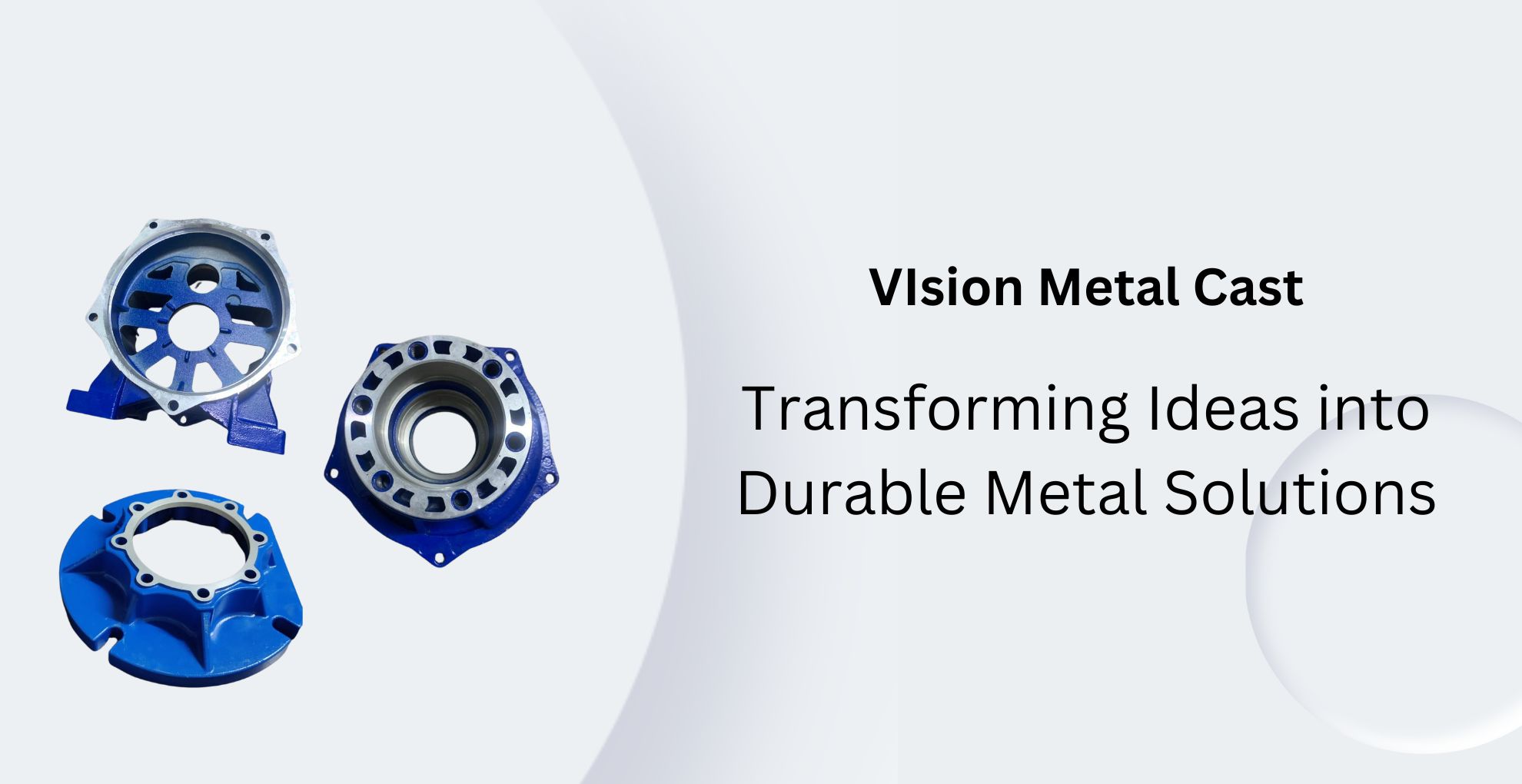

At Vision Metal Cast, we specialize in delivering precision-crafted casting solutions across industries. With advanced technology and strict quality control, we transform ideas into reliable, high-performance components. From design to production, our expertise ensures innovation and excellence at every step.

We specialize in crafting solutions tailored to your exact specifications. By collaborating closely with you, we develop products that meet your precise needs, using innovative processes and cutting-edge technology.

Our team can transform your older products into modern, high-performing assets. Whether it’s an upgrade in design or functionality, we breathe new life into existing products with enhanced aesthetics and improved performance.

We ensure seamless delivery of your orders, distributing products to your desired locations on time. Our efficient logistics network guarantees that your products reach you wherever you need them.

On-Time Delivery

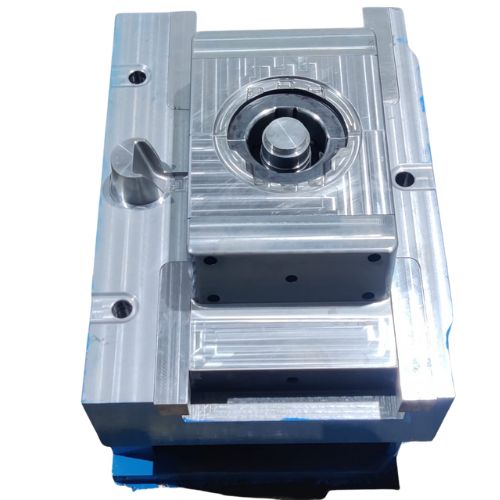

Comprehensive Collection of Machining

procedures: Milling, Turning, Drilling-Tapping, etc.

Superior R&D Capability

Extensive Production Experience

With over 10 years of experience in Vision Metal provides technical support and produces high precision aluminum parts for all type Industries.

Strong Production Capability

High-Quality Assurance

Strong R&D Capability

Strict Quality Control

Wide Range of Aluminum

Material

Providing Turnkey Solution

High Mix Low to Medium Projects

Four Facilities Near Shanghai

Rapid Prototyping Service

Professional Evaluation & DFM Support

Wide Range of Finishing

Broad Scope of Material

Metal: Aluminum, Zinc, Copper, Stainless Steel, etc

Multi-axis CNC Machinery(3 axes,4axes,5 axes & 7 axes)

Small Order Acceptance

Attractive Product Appearance

Wide Range of Finishings

Strict Quality Control

Superior Engineering Capability

Well-package Design

ROHS & REACH Compliance

Industries We Serve

Electronic

Fire Fighting

General Engineering

Health Care

Agriculture

Textile

Aerospace

Railway

Marine

PRODUCTS

Clientele